Design principles and main advantages of permanent magnet stepper motors

1. Definition of permanent magnet stepper motors

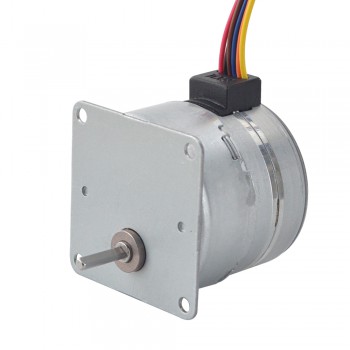

Permanent magnet stepper motors (PM motors) are stepper motors that use permanent magnet materials as rotors. The rotor uses permanent magnet materials and operates continuously based on the principle that like poles repel each other and opposite poles attract each other between the rotor and the stator. Permanent magnet stepper motors are usually inner rotor type motors, and the outer surface of the cylindrical rotor is evenly distributed with N and S poles.

2. Principle of permanent magnet stepper motors

The working principle of permanent magnet stepper motors is based on magnetic field interaction. When the stator winding is energized, a magnetic field is generated. This magnetic field interacts with the permanent magnets on the rotor to generate a torque, causing the rotor to rotate according to the set step angle. By changing the order and frequency of the stator winding, the direction and speed of the rotor can be controlled.

3. Specifically, when the stator winding is energized, a magnetic field is generated, which interacts with the permanent magnets on the rotor to generate a torque, causing the rotor to rotate according to the set step angle.

3. Design principles of permanent magnet stepper motors

1. Material selection principles: The performance of permanent magnet motors depends largely on the permanent magnet materials used. High-performance permanent magnet materials can not only improve the power density of the motor, but also reduce the size and weight of the motor. When selecting materials, the magnetic properties, thermal stability and cost of the material need to be considered. For high-efficiency and high-speed motors, NdFeB is usually selected as a permanent magnet to obtain higher magnetic density.

2. Motor structure design: The structural design of high-efficiency and high-speed permanent magnet motors is the key to their performance. The optimized design of the motor's windings, air gaps, rotors and stators can effectively reduce eddy current losses, copper losses and iron losses, thereby improving the overall efficiency of the motor. In the design, a combination of slotted rotors and slotless stators can be used to reduce the cogging effect and improve the output stability of the motor.

3. Cooling system: Under high-speed operation, permanent magnet motors will generate a lot of heat, resulting in increased temperature rise, affecting the performance and life of the motor. Therefore, a reasonable cooling system design is necessary to ensure that the motor can still operate stably at high temperatures.

4. Control strategy: The control strategy of permanent magnet motor needs to be adjusted according to its operating conditions and load type. For example, the permanent magnet motor running on the grid needs to maintain a high power factor under rated conditions, and the power factor is usually required to be as close to 1 as possible. In addition, in order to ensure that the motor has a certain overload multiple, the power angle is usually small, about 30 degrees.

5. Other design elements: The application of technical means including rotor skew pole, single-layer wiring, spiral water cooling, etc. can effectively improve the torque pulsation of the motor, increase the slot full rate, and reduce the temperature rise.

4. Main advantages of permanent magnet stepper motor

1. High efficiency: Due to its unique magnetic field generation method, permanent magnet stepper motor uses permanent magnets instead of traditional excitation coils to generate magnetic fields, which reduces energy loss and enables its efficiency to reach more than 90%, which is significantly higher than traditional motors.

2. High power density: Due to the use of high-performance permanent magnet materials, permanent magnet stepper motors can output higher power at the same volume and weight. This feature makes it particularly outstanding in space-constrained application environments, such as electric vehicles, robots, and portable devices.

3. Wide operating range: Permanent magnet stepper motors have a wide operating range and can work stably under a variety of working conditions. They can still maintain good performance under low speed and high load conditions, and are particularly suitable for applications that require frequent starting and stopping, such as elevators and lifts.

4. Low maintenance cost: Due to the brushless design, the wear and replacement of carbon brushes are eliminated, and the mechanical wear of permanent magnet stepper motors is small, which reduces maintenance costs. This low maintenance requirement enables the motor to maintain high reliability in long-term operation and reduces downtime.

5. Simple structure and high reliability: The structure of permanent magnet stepper motors is simpler, and cumbersome components such as armature windings and commutators are removed, which significantly reduces the failure rate during operation. Its high efficiency characteristics also make the temperature rise inside the motor lower, further improving the reliability of the motor.

6. Flexible magnetic circuit design: Permanent magnet stepper motors can be designed with large air gaps according to actual working requirements, which facilitates the construction of new magnetic circuits. This design flexibility enables the motor to adapt to different application scenarios and requirements.