Design features and application areas of hollow shaft stepper motors

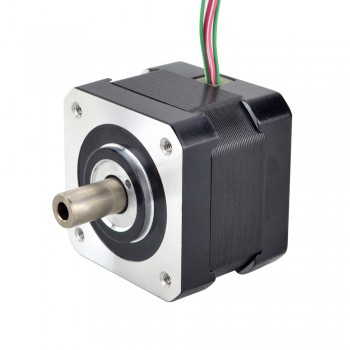

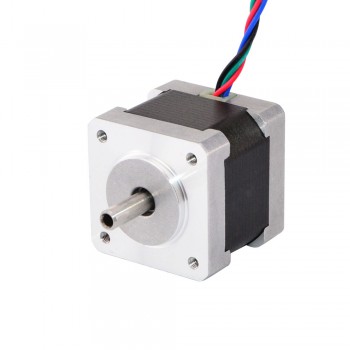

1.The meaning of hollow shaft stepper motor

The hollow shaft stepper motor is a special stepper motor, which is characterized by a hollow motor shaft. This design allows the motor shaft to be used not only to transmit torque, but also allows other devices (such as optical shafts, slender tools, etc.) to be inserted through the shaft center, thereby achieving more complex application requirements.

2.Working principle of hollow shaft stepper motor

The working principle of hollow shaft stepper motor is mainly based on electromagnetic induction and stepper drive control. This motor consists of a rotor and a stator, in which the stator generates an electromagnetic field, which acts on the rotor to cause it to rotate. By inputting a specific pulse signal, the stepper drive can control the step and speed of the motor. One of the design features of the hollow shaft stepper motor is that the center of its rotor is hollow. This design allows the shaft center to pass through, which is suitable for application scenarios where other devices or transmission parts need to pass through the rotor shaft. In addition, the design and application of hollow shaft stepper motors also optimize mechanical design, facilitate wiring, and save design space and production costs. For hollow shaft stepper motors with precision requirements, they have very high requirements for the precision of the hollow shaft or inner hole diameter and thread, mainly because most of these motors are customized to meet the needs of using third-party trapezoidal screws or ball screws. Such high-precision requirements ensure the mechanical accuracy and operating accuracy of the stepper screw motor

3.Design features of hollow shaft stepper motors

1.Hollow shaft design: Compared with traditional motors, the center of the rotor of the hollow shaft stepper motor is empty and can pass through the axis, which is suitable for those application scenarios where other equipment or transmission parts need to pass through the rotor shaft.

2.High-precision positioning: Since the step distance and angle of rotation are controllable each time, the hollow shaft stepper motor can achieve high-precision positioning movement to meet the needs of high-demand industrial applications.

3.High efficiency: The hollow shaft stepper motor adopts digital control technology, which can provide high-efficiency operation while achieving high precision and saving energy.

4.Programmability: The operation mode and parameters of the hollow shaft stepper motor can be controlled by programming, and can be adjusted according to different application requirements, with good flexibility and scalability

4.Specific application areas of hollow shaft stepper motors

1.Automation equipment: Hollow shaft stepper motors are widely used in automation equipment, such as robots, automated production lines, CNC machine tools, etc. In these devices, hollow shaft stepper motors can provide precise position control and motion control, while facilitating the passage of cables, trachea, etc.

2.Medical equipment: In the field of medical equipment, hollow shaft stepper motors are often used in surgical robots, medical imaging equipment, laboratory automation equipment, etc. These devices have high requirements for precision and reliability, and hollow shaft stepper motors can meet these requirements and facilitate the layout of cables, trachea, etc.

3.Printing equipment: In printing equipment, hollow shaft stepper motors can be used to drive printing rollers, paper conveying and other components. The hollow shaft design can facilitate the passage of cables, trachea, etc., and improve the integration and reliability of the equipment.

4.Textile machinery: In textile machinery, hollow shaft stepper motors can be used to drive components such as yarn winding and looms. The hollow shaft design can facilitate the passage of cables, air pipes, etc., and improve the integration and reliability of the equipment.

5.Stage equipment: In stage equipment, hollow shaft stepper motors can be used to drive components such as stage lifting and stage rotation. The hollow shaft design can facilitate the passage of cables, air pipes, etc., and improve the integration and reliability of the equipment.

6.Aerospace: In the field of aerospace, hollow shaft stepper motors can be used to drive components such as rudders and landing gear. The hollow shaft design can facilitate the passage of cables, air pipes, etc., and improve the integration and reliability of the equipment.

7.Vehicle engineering: In vehicle engineering, hollow shaft stepper motors can be used to drive components such as electric windows and seat adjustments. The hollow shaft design can facilitate the passage of cables, air pipes, etc., and improve the integration and reliability of the equipment.

5.Conclusion

With the development of microelectronics and computer technology, the demand for stepper motors is increasing day by day, and they are used in various fields of the national economy. Hollow shaft stepper motors rely on their professional technology and experience in design, manufacturing and application to provide a rich product range to meet the needs of different customers and different applications